About

About

WALTA stands for “We Activate Life To Anyone”, embodying our mission to enhance smart living and add value to the electronics industry through connections. Our connectivity solutions extend beyond electronics to serve the industrial, medical, telecommunications, and automotive sectors.

Founded in 1992 and headquartered in Taipei, Walta Electronic focuses on connector design and manufacturing. In 2014, we expanded our capabilities to include cable assembly, broadening our range of service offerings to meet emerging market demands and expectations. Today, we provide a comprehensive range of I/O connectors and cable solutions. We excel in delivering customized solutions, with our in-house design team working closely with clients to mold, test, and produce tailored products that meet specific needs.

With over 30 years of industry experience, we understand that quality, cost-effectiveness and technical proficiency are the keys to being a trustworthy supplier. These values are at the core of our service philosophy as we work closely with our customers and partners. Our commitment is to provide the highest quality services and products to gain competitive advantage for our customers. For us long-term relationships are built on trust and shared success. We have different ISO certifications and connector certifications to meet industry benchmarks and customized products.

1992-2003

- Dec.1992 -Walta Electronics Co., Ltd. was officially established in Taipei.

- Jan.1994 - Began manufacturing: Pager Connectors.

- Mar.1994 - Expanded product line: Mobile I/O Connectors.

- May.1995 - Established the first factory in Taiwan.

- Jun.1995 - The Taiwan factory achieved ISO9001 certification.

- Apr.1999 - Established a branch office in Hong Kong.

- Jun.1999 - Expanded product line: PDA I/O Connectors.

- Aug.1999 - Established the first factory in Mainland China.

- Nov.1999 - The Mainland China factory achieved ISO9001 certification.

- Jan.2001 - Expanded product line: Laptop Connectors.

- Apr.2003 - Established the second factory in Mainland China.

2005-2023

- Jan.2005 - Walta Electronics (Shenzhen) Co., Ltd. was officially established in Shenzhen.

- Jul.2005 - The second factory in Mainland China achieved ISO9001 certification.

- Aug.2006 - Both factories in Mainland China achieved ISO14001 certification.

- Aug.2006 - Established a branch office in Shanghai.

- Jun.2007 - Expanded product line: HDMI series.

- Jan.2008 - Expanded product line: USB, MINI USB, MICRO USB Connectors, T-Flash sockets, and other products.

- Mar.2008 - Received certification from HDMI and USB product associations.

- May.2014 - Expanded product line: Cable assembly.

- Dec.2015 - Received Type C 3.1 certification.

- Aug.2020 - Received HDMI A 2.1 certification.

- Aug.2021 - Received Type C 4.0 certification.

- Jul. 2023 - Expanded product line: DP 2.1 Connectors

Philosophy

Innovation & Growth

Within rapid changing environment, we consistently introduce new products and explore new methods to deliver superior solutions to enhance customer experience and boost market competitiveness.

Simplicity & Efficiency

Walta focuses on simplifying processes and efficient resource use, enhancing production efficiency, product quality, and customer service. We aim to reduce waste, improve operations, and deliver efficient services.

Sustainable Development

With foresight and strategic planning, Walta focuses on the next 5 to 10 years of development. We prioritize long-term benefits to ensure stable and healthy growth, creating lasting value for employees, customers, and shareholders.

Efficient Collaboration

Walta pursues win-win cooperation through international collaborations for new profit growth. We focus resources, work on product value chains, and enhance core competitiveness to deliver exceptional products and services.

Excellence in Service and Custom Solutions

Exceptional service is the cornerstone of our success. Guided by modern service principles, strengthening our service philosophy and improving service quality are essential for gaining a competitive edge and ensuring the sustainable growth of our business. Our service philosophy is embodied in the following aspects:

定制化(Customization)

Designing and manufacturing connectors and cables to the specific requirements of our clients, ensuring every product meets or exceeds their expectations.

迅捷性(Celerity)

Responding swiftly to client inquiries and needs, offering prompt technical support and after-sales service.

可信度(Credibility):

Building long-term, stable partnerships based on integrity, allowing clients to feel our sincerity and professionalism.

持續改進(Continuous Improvement)

Continuously improve the quality of products and services, and actively research new technologies to ensure that our solutions can meet the market changes and customer needs.

Sustainability

ESG (environmental, social and governance) strategies have become integral to corporate success.

At Walta Electronic, ESG principles are integral to our business strategy and guide our actions as a responsible corporate citizen. We are dedicated to creating long-term value for all stakeholders while positively impacting society and the environment.

Environmental Stewardship

At Walta Electronic, we are committed to minimizing our environmental impact and promoting sustainability in everything we do. We strive to reduce our carbon footprint through energy-efficient practices, waste reduction initiatives, and responsible sourcing of materials. Our eco-friendly practices aim to create a healthier planet for future generations.

Social Responsibility

We prioritize social responsibility by supporting local communities through philanthropy and engagement programs. Our initiatives focus on education, healthcare, and poverty alleviation, aiming to foster inclusivity and diversity. By empowering individuals, we strive to create positive social change in the communities where we operate.

Governance Excellence

We prioritize transparency, integrity, and accountability in our governance. Upholding high standards ensures ethical decision-making and responsible business practices. We maintain open communication with stakeholders to build trust among investors, customers, employees, and partners.

Quality: Our Guiding Principle

We adhere to the principle of enhancing quality to sustain enterprise vitality, viewing it as the cornerstone of our development. Dedication to continuously improving product quality ensures each connector meets the highest standards, laying a solid foundation for long-term growth. These values reflect our commitment to quality, efficiency, customer-centricity, and excellence in manufacturing, aiming to increase efficiency, reduce costs, and provide proactive service.

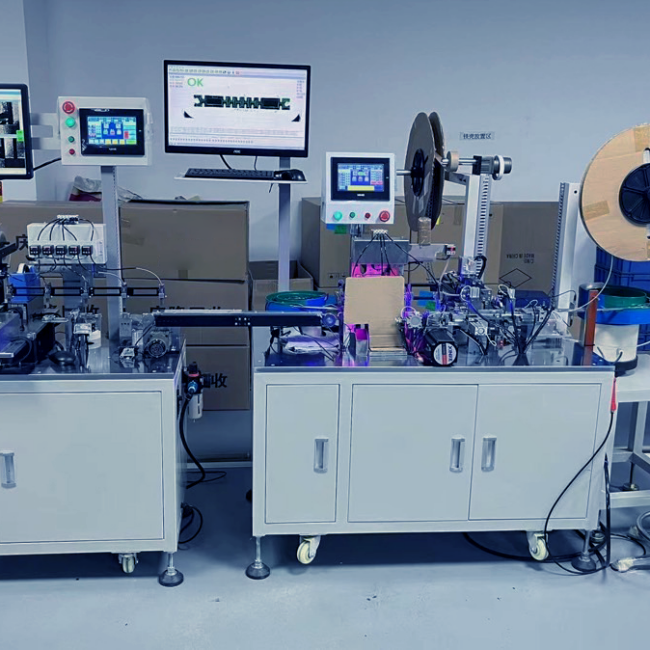

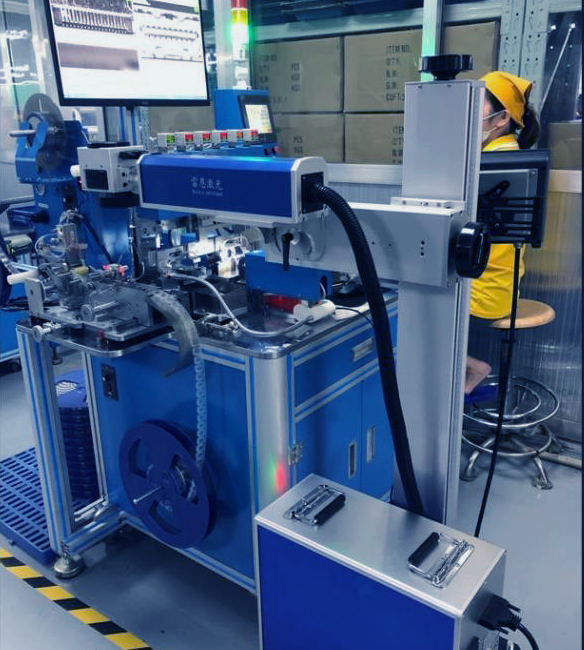

Increase Efficiency

We strive to "increase efficiency to strengthen corporate flexibility" by optimizing processes and introducing automated equipment. This enhances our production efficiency and our ability to swiftly respond to market changes.

Reducing Costs

To remain competitive in the market, we reduce costs through lean production and effective resource management, we lower production costs and offer competitive pricing, allowing our customers to enjoy high-quality products with excellent value.

Proactive Service

We uphold the principle of "Proactive service to achieve comprehensive customer satisfaction." We actively communicate with clients to understand needs and challenges to provide professional, prompt, and considerate service.

Innovation and Technology

Since 1992, our mission has focused on efficient, practical management and production automation. We design and develop I/O connectors, socket connectors, USB connectors, HDMI connectors, DisplayPort connectors, SATA connectors, and other related products, using advanced software to innovate continuously. Our approach emphasizes increased production capacity, shorter lead times, and stabilized product quality, enhancing efficiency and competitiveness in the electronics industry.

Professional Design Team

Our design engineering personnel, proficient in mold making, stamping, injection molding, and other technical aspects, ensure the technical superiority of each product. Our professional design team utilizes software such as AutoCAD and Pro-E, along with related validation software like stress and strain analysis and high-frequency testing analysis, to conduct precise 3C product connector designs.

Efficient Product Development

Product development to mass production takes only 21 days, ensuring efficiency. Our technical team possesses extensive experience and professional knowledge, enabling rapid response to market demands and providing efficient solutions.

Precision Design

We utilize advanced drawing and analysis software to prevent product failures beforehand. Our related design departments are dedicated to the design, development, and maintenance of high-precision I/O connector molds, equipped with imported precision equipment and various verification testing devices to ensure professional product quality.

Patents and Intellectual Property

We hold multiple patents and certifications from various associations, safeguarding intellectual property for both parties. Our molds use imported steel materials such as FUTABA from Japan, VIKING from Sweden, and SKD-61 from Japan, subjected to vacuum high-temperature quenching to ensure product longevity.

Our mold department, with over 30 years of professional experience, features a team of more than 20 experts who can develop products to the T1 sample stage within 21 days. Beyond manufacturing, our in-house design team collaborates closely with global customers, fostering innovation and growth through data-driven insights. This approach ensures our solutions are accurate, reliable, and cost-effective, aligning with market demands and trends.